Heavy Industries

Customer Projects

Noise Reduction for Noise-Sensitive Operation

A leading manufacturer of mobile machinery approached us with the goal of acoustically optimizing their new hybrid drivetrain. The objective was to significantly reduce operational noise emissions, especially for use cases involving:

-

Urban environments with strict noise regulations,

-

Operation near residential areas, and

-

Nighttime construction or maintenance work.

Technical Requirements Defined by the Customer:

-

Analysis and quantification of structure-borne and airborne noise sources within the powertrain.

-

Identification and mitigation of dominant eigenfrequencies in the 20–500 Hz (low-frequency structure-borne noise) and 1–8 kHz (high-frequency airborne noise) ranges.

-

Development of acoustically optimized operating strategies for electric drive modes in noise-sensitive applications.

-

Seamless integration of all simulation methods into the existing CAE development chain.

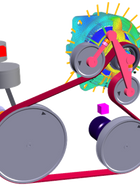

Multi-Body Simulation-Based Analysis and Optimization

Dynamic System Modeling

A detailed MBS model of the complete drivetrain was created—including the internal combustion engine, generator, electric motor, clutches, transmission, and auxiliary components. The model accounted for kinematic couplings, bearing stiffness, nonlinear damping elements, and flexible structural components.

NVH Analysis and Modal Evaluation

Transient operating scenarios were simulated to identify vibration transmission paths and critical structural resonances. Modal analysis and spectral evaluation were used to locate and understand excitation mechanisms for problematic frequencies.

Material and Structural Optimization

Based on the simulation results, design proposals were made for noise-reducing improvements—such as targeted stiffness increases in frame elements, the use of acoustic isolators, and the integration of viscoelastic damping materials.

Scenario-Based Simulation for Real-World Use Cases

Typical use cases, such as nighttime startup procedures and work cycles involving transient load peaks, were simulated to validate the effectiveness of all noise mitigation measures under realistic conditions.

Outcome

By applying MBS and acoustic simulation methods, noise emissions in critical operational scenarios were reduced by up to 12 dB(A). All optimization steps were implemented virtually, eliminating the need for expensive early-stage prototype testing. The validated measures were transferred into the customer’s series development process and support compliance with international noise regulations